Appiicarit Standards

- Steel Check Valves API 594/API 6D

- Steel Check Valves ISO 14313

- Steel Valves ASME B16.34

- Face To Face ASME B16.10

- End Flanges ASME B16.5

- Butt Welding Ends ASME B16.25

- Inspection and Test API 598/API 6D

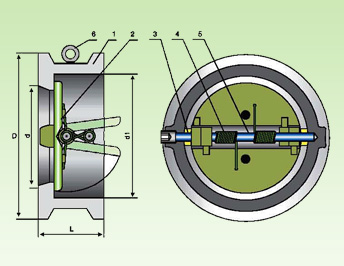

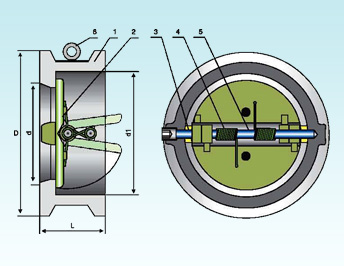

Design Descriptions

- One Piece Body

- Renewable Split Disc

- Horizontal Or Vertical Service

- Wafer Ends

- Available With Flanged Ends

Range Of Materials

| S. No. | Part Name | Carbon Steel | ASTM Material 1/1/4cr-1/2 mo | Low Temp Carbon Steel |

| 1 | Body | A216-WCB | A351-CF8M | A352-LCB |

| 2 | Plate | A216-WCB+CR13 | A351-CF8M+HF | A350-LCB+CR13 |

| 3 | Stop Pin | A276-420 | A278-304 | A276-420 |

| 4 | Back Spring | A313-304 | A313-316 | A313-304 |

| 5 | Hinge Pin | A276-420 | A276-304 | A276-420 |

| 6 | Eye Bolt2 | Carbon Steel |

Dimensional Datas Of Ansi Class 150 LB

| NPS | 2 | 2/1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | in |

| DN | 60 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | mm |

| L | 2.38 | 2.62 | 2.88 | 2.88 | 3.88 | 5 | 5.75 | 7.12 | 7.25 | 7.5 | 8 | 8.62 | 8.75 | in |

| 60 | 67 | 73 | 73 | 98 | 127 | 146 | 181 | 184 | 191 | 203 | 219 | 222 | mm | |

| D | 4 | 4.88 | 5.38 | 6.75 | 8.62 | 10.88 | 13.25 | 16 | 17.62 | 20.12 | 21.5 | 23.75 | 28.12 | in |

| 103 | 122 | 135 | 173 | 220 | 277 | 337 | 407 | 488 | 512 | 547 | 604 | 715 | mm | |

| d | 2 | 2.5 | 3.25 | 4 | 6 | 8 | 10 | 12 | 13.75 | 15.75 | 17.75 | 19.75 | 23.62 | in |

| 51 | 65 | 80 | 102 | 152 | 203 | 254 | 305 | 350 | 400 | 450 | 500 | 600 | mm | |

| D1 | 2.25 | 2.88 | 3.5 | 4.25 | 6.25 | 8.25 | 10.5 | 12.12 | 14 | 16 | 18 | 19.88 | 23.75 | in |

| 56 | 73 | 88 | 108 | 160 | 210 | 266 | 310 | 355 | 405 | 455 | 505 | 605 | mm | |

| Wt. | 2 | 3 | 4 | 6 | 13 | 25 | 39 | 54 | 80 | 117 | 138 | 163 | 331 | kg. |

Dimensional Datas Of Ansi Class 300 LB

| NPS | 2 | 2/1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | in |

| DN | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | mm |

| L | 2.38 | 2.62 | 2.88 | 2.88 | 3.88 | 5 | 5.75 | 7.12 | 8.75 | 9.12 | 10.38 | 11.5 | 12.5 | in |

| 60 | 67 | 73 | 73 | 98 | 127 | 146 | 181 | 222 | 232 | 264 | 292 | 318 | mm | |

| D | 4.25 | 5 | 5.75 | 7 | 9.88 | 12 | 14.12 | 16.5 | 19 | 21.12 | 30.38 | 25.62 | 30.38 | in |

| 110 | 128 | 147 | 179 | 249 | 305 | 359 | 420 | 483 | 537 | 594 | 652 | 772 | mm | |

| d | 2 | 2.5 | 3 | 4 | 6 | 8 | 10 | 1200 | 14 | 16 | 18 | 20 | 24 | in |

| 51 | 65 | 80 | 102 | 152 | 8.25 | 254 | 305 | 350 | 400 | 450 | 500 | 600 | min | |

| D1 | 2.25 | 2.88 | 3.5 | 4.25 | 6.38 | 203 | 10.5 | 12.25 | 14 | 16 | 18 | 20 | 24 | in |

| 58 | 73 | 88 | 108 | 160 | 210 | 266 | 310 | 355 | 405 | 455 | 505 | 608 | mm | |

| Wt. | 3 | 4 | 6 | 8 | 18 | 31 | 51 | 77 | 117 | 190 | 200 | 265 | 410 | kg. |