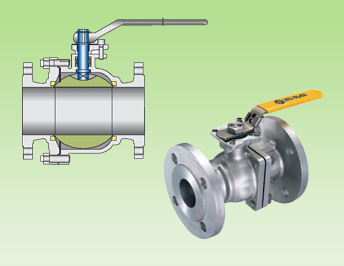

Design

NU-TECH steel ball valves are designed and manufactured to provide maximum service life and dependability. All gate valves are full ported and meet the design requirements of American Petroleum Institute standard API608 &API 6D. British standard Bs5351 and generally, Conform to American Society of Mechanical Engineers standard ASME B16.34. Valves are available in a complete range of body/bonnet materials and trims.

Available Modifications Fon NU-Tech Valves

- Trim Changes

- End Connection Modifications

- Packing and Gasket Change

- Operator Mounting

- Handwheel, Extensions

- Pressure Equalizing

- Customer Specified Coatings

- Weld End Bore Changes

- Oxygen & Chlorine Clearing & Packaging

Operation

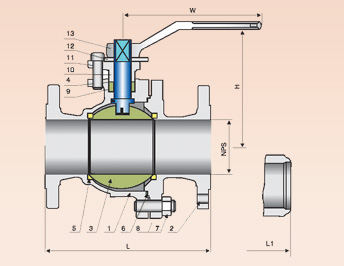

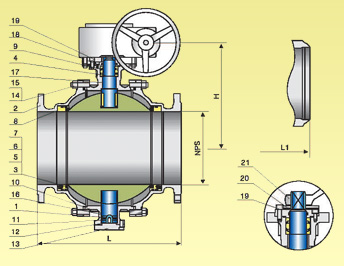

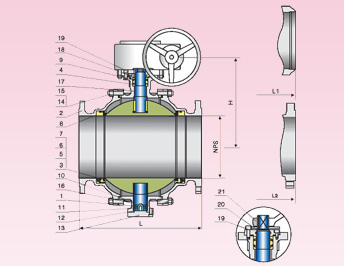

Extended lever for easy operation. also available with gearing motor actuators, pneumatic or hydraulic actuators for more difficult services.

Body & Bonnet

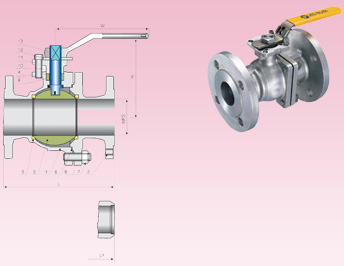

Split or 3-piece, split body & bonnet for 12" & small disassembles easily for repair component.

Bore

Full bore or reduced bore. full-bore design provides exceptional flow control.

End Connections

A choice of flanged, Rh flanged or butt welding end for piping flexibility.

Ranse of Materiamf

Standard body/bonnet materials include nine grades of carbon, low alloy & stainless steels. For special applications they can be supplied in other grades of alloy & stainless steel. Threre's a full range of trim materials to match any service optional packing & gasket materials are available for a full range of service conditions.

Packing

Std packing multiple V-teflon packing. combined with live loading, maintains packing compression under high-cycle and severe service applications. Graphite packing is used for high-temperature situation.

BPS

Blow-out proof stem A pressure-safe stem shoulder design that protects against failure under excess pressure.